When I had the idea for this T-Shirt Crossover project, I really wanted to see first hand what the benefits and drawbacks of heat transfers.

It's one thing for me to read all the threads here and have "book knowledge" of how heat transfers work; I'm finding it something totally different to actually press transfers to shirts.

First Lesson

The first thing I learned about plastisol transfers was that not all plastisol transfers are equal. Not that I got poor quality transfers, just that not all transfers are as easy to apply (for a newbie like me) as others.

I think for some reason I expected I would heat up my press, pre-heat the garment, press the transfer for a few seconds, and viola, there's my perfect shirt.

My reality was that there is a lot more testing of temperature, getting the right pressure, testing how long to press (dwell times), figuring out how fast to peel it off on a hot peel or how cool to let the transfer get for a cold peel.

On To The Plastisol Transfer Tests

Companies contacted:

First Edition

Dowling Graphics

Howard Sportswear

KE Moto Graphics

Transfer Express

VersaTranz

FMExpressions

Image Setters

Criteria:

For this review, I'm going to make up some very unscientific newbie criteria to rate each company on I'll use a scale of 1 to 5 teestars, with (1)

I'll use a scale of 1 to 5 teestars, with (1)

![Image]()

being not so good and (5)

![Image]()

being the best. This is just based on my personal experience with each company.

Presentation of Sample Package - includes number of transfers, instructions, variety, company information, ordering information received, pricing info received. Basically my impression of how complete the information was that I received that would help me do business with the company.

Responsiveness - how fast the company responded to all email and/or phone communication. This also includes how fast the samples arrived.

Transfer Ease of Use For This Newbie - this was one of the most important factors for me. Simply put, how easy it was for me (a complete newbie to heat pressing transfers) to press a transfer that I would feel comfortable selling to a retail customer. If I could follow the instructions they sent and get the desired result with very little "messing around" (pressure, changing temperature, testing dwell times, etc), they got a higher rating here.

Likelihood I'd Use Them on Future Orders - how likely I would use the company for future custom transfer orders.

Variety of Custom Transfer Printing Services - how varied their screen printed transfer printing services were based on the information I received. Like do they do rhinestones, stock transfers, hot peel, puff, 4+ color transfers, existing designs you can customize to fit your needs, etc.

*Quality - overall quality of the transfers

Reviews:

First Edition Screenprinting

Website: First-Edition.com

Phone: 1-800-872-6760

Presentation of Sample Package -

![Image]()

Responsiveness -

![Image]()

Transfer Ease of Use For This Newbie -

![Image]()

Likelihood I'd Use Them on Future Orders -

![Image]()

Variety of Custom Transfer Printing Services -

![Image]()

*Quality -

![Image]()

After my initial hurdles contacting First-Edition Screen Printing by email (later solved by Badalou ), they were actually the first one of the 8 companies I contacted to actually have the sample transfers at my door.

), they were actually the first one of the 8 companies I contacted to actually have the sample transfers at my door.

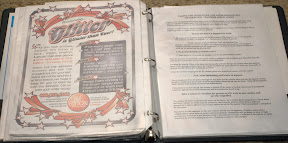

Out of all the sample packages I received, the package from First Edition was the most informative. They sent a binder that had information on the company history, detailed information on the different transfer types, a huge variety of sample transfers for me to try and even a sample printed t-shirt.

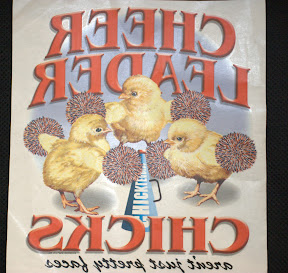

![Image]()

They sent cold peel, hot split, double print hot split, glitter, transfers for nylon, sample numbers, all kinds of good stuff.

The first transfer I tried from First Edition was one of the hot split transfers.

I pre-heated the press, pre heated the garment to get the moisture out, followed the instructions and didn't do too well on my first try:

I have to admit I was slightly disappointed at this point, since I had it in my mind that they would "just work". After talking (via email) with Janet from First Edition and reading through the info they provided, it can sometimes take a bit of testing of temperatures, pressure settings and dwell times to get transfers to come out right.

I found it's sort of like those instructions that come with Microwave meals that tell you that their instructions were for a 1000 watt microwave, so you may need to adjust your results based on your microwave brand and wattage. Not all heat presses heat the same or give the same pressure, so there will be times when you need to fiddle around with it to see what works.

I decided to come back to the First Edition transfers a a few days later once I had a better hang of things. I also had to do a better job of taking before and after photos

This time I tried one of the hot split transfers and got a bit better result:

I still wasn't getting enough ink on the shirt and consistency was still off.

The actual feel of the print on the shirt was very nice though:

I adjusted the pressure a bit and increased the temperature and tried another of the same type transfer:

The results were a bit better, but still not perfect:

A few more adjustments to the pressure and an increased dwell time (how long to press the transfer) and I got a much better result:

![Image]()

Overall, I thought First Edition was very helpful in answering my questions, sent out a great sample package, but I feel like the transfers are a bit too tricky for my current heat press experience level.

Dowling Graphics, Inc

Website: DowlingGraphics.com

Phone: 1-800-749-6933

Presentation of Sample Package -

![Image]()

Responsiveness -

![Image]()

Transfer Ease of Use For This Newbie -

![Image]()

Likelihood I'd Use Them on Future Orders -

![Image]()

Variety of Custom Transfer Printing Services -

![Image]()

*Quality -

![Image]()

Dowling Graphics was the first company to get back to me via my email inquiry. I got my plastisol transfer samples a few days after the confirmation email I received from them.

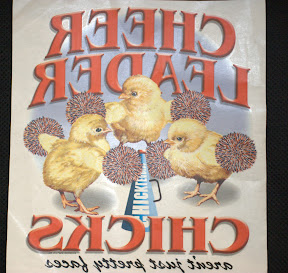

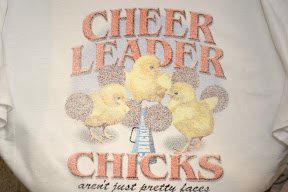

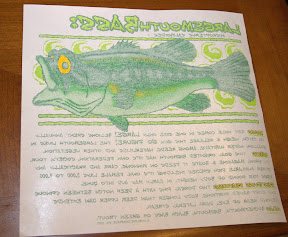

Their sample transfer package included some very nice full sized transfer sheets with a variety of full color stock images. They included their pricing sheet, stock catalogs even some very cool rhinestud transfers. I would have to say that Dowling Graphics included the most complex transfer designs (multi-colored) which helped to show their full color capabilities.

The first transfer I tried from Dowling Graphics was one of their hot split transfers. This picture is of the transfer sheet AFTER it was applied:

The transfer almost came out right on the first try. I don't think enough of the ink transferred to the shirt and when I hot peeled the transfer, it seemed to pull the ink off the shirt a bit:

A closer look shows some of the areas of the design that were missing ink or that were a bit patchy.

Most of the design transferred well though. I really think with more practice, they would come out perfect:

My next try with the same type transfer didn't come out as well. Here's the "before":

Here's a closeup of the transfer sheet:

Here are some "after" photos. Again, not enough of the ink transferred to the shirt which left splotchy areas in the finished design:

I had similar hit and miss results with their hot peel transfers for white/light garments.

Here's a before picture of the transfer sheet:

And an after picture that shows the light ink coverage:

I did get one transfer for light t-shirts to come out just about perfect.

The pressed transfer:

Unfortunately, I don't remember the exact settings I needed to get it to come out "just right".

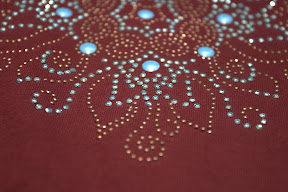

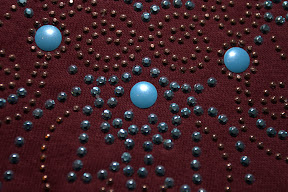

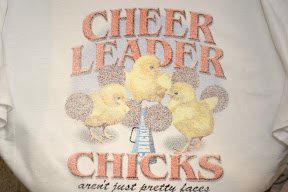

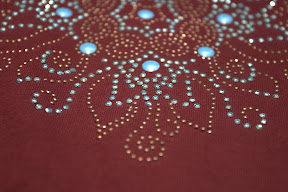

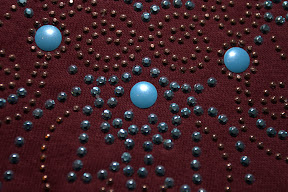

I was very impressed with the rhinestone/rhinestud type transfers that Dowling Graphics sent. Initially I didn't see the appeal of this type of decoration, but after seeing how easy it was to apply, and how it looked on a finished t-shirt, I could see offering custom rhinestud transfers (or even stock ones) for sale. With the right creativity, I could see how you could combine a rhinestone/crystal transfer with a plastisol transfer to create a really nice finished design.

Here's the transfer sheet:

And a few pictures of the finished rhinestone transfer on a maroon teeshirt. Since this tshirt didn't have a side seam, I actually pressed this transfer as a "wrap around" design that is partly on the front and partly on the back of the tee.

I even made a cute t-shirt for my daughter

Once I get better at the hot split transfers, I could see myself ordering from Dowling Graphics. Out of the hot peel, hot split and cold peel transfers I tried, I liked the feel of the hot split transfer the best.

I really liked the rhinestone transfers. I don't know if they do custom rhinestone transfers, but it's something I would look into for certain designs now that I've seen it in action.

Howard Sportswear Graphics Express, Inc

Website: Howard Sportswear Graphics

Phone: 1-866-695-8196

Presentation of Sample Package -

![Image]()

(0 teestars means not applicable  )

)

Responsiveness -

![Image]()

Transfer Ease of Use For This Newbie -

![Image]()

Likelihood I'd Use Them on Future Orders -

![Image]()

Variety of Custom Transfer Printing Services -

![Image]()

*Quality -

![Image]()

I initially emailed Howard Sportswear and got an email back from them a few days later asking me to call them for more info. I'm normally an email kinda guy, but I had heard good things about their company from posts here in the forums, so I gave them a call.

I talked to one of their employees who gave me some good information about the company, asked me about my needs, and said she would send out a sample pack. I never heard from them again.

UPDATE (3=16-07): After I heard back from Versatranz, I decided to email Howard Sportswear this week to see what happened to my samples.

I got an email back pretty quick that said that they held up sending the samples because they were waiting on new catalogs to be printed, but if I wanted, they could send me the samples without the catalog. I wish they would have followed up earlier to let me know about the delay, but at least now I know what happened. I got a shipment notification today that the sample pack was shipped.

KE Motographics

Website: K E Motographics prints custom heat transfers using your artwork, as well as printing directly onto clothing. We can print either screenprinted heat transfers or color laser heat transfers. Give us a call or send an email to discuss which is best for

Phone: 1-800-563-1873

Presentation of Sample Package -

![Image]()

Responsiveness -

![Image]()

Transfer Ease of Use For This Newbie -

![Image]()

Likelihood I'd Use Them on Future Orders -

![Image]()

Variety of Custom Transfer Printing Services -

![Image]()

*Quality -

![Image]()

Thanks to Jasonda, I was able to get in contact with this custom transfer supplier from the west coast. They got back to my initial email pretty quickly and followed up questions to make sure I got the right samples that would demonstrate their work. Nice friendly, down to earth emails.

The samples I got from the company came in a plain letter sized envelope with a packing slip and a few 1-2 color hot peel transfers.

I fired up my heatpress and followed their instructions to test their transfers.

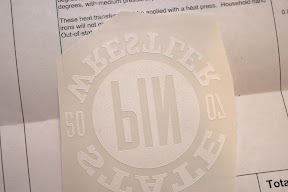

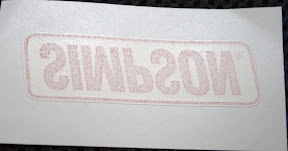

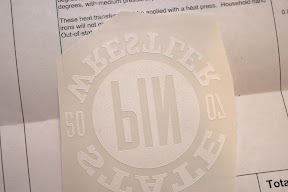

Here's the before transfer:

And a near perfect after transfer photo:

I say "near" perfect because I think I may not have had enough pressure. It seems like this transfer sat on top of the shirt more than I thought it should.

I think with a bit more pressure, and maybe even setting the temperature a bit hotter, the ink would have smooshed (technical term ) on the shirt fibers a little better.

) on the shirt fibers a little better.

Although, the KE Motographics "package" was very simple and to the point, their transfers worked pretty well on the first go without much fiddling.

Stahl's Transfer Express

Website: transferexpress.com

Phone: 1-800-622-2280

Presentation of Sample Package -

![Image]()

Responsiveness -

![Image]()

Transfer Ease of Use For This Newbie -

![Image]()

Likelihood I'd Use Them on Future Orders -

![Image]()

Variety of Custom Transfer Printing Services -

![Image]()

*Quality -

![Image]()

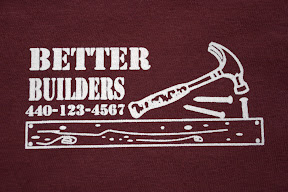

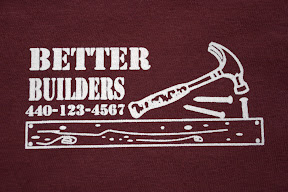

The folks from TransferExpress got back to me the same day I sent out an email requesting more information. They answered my question on which of their transfers offered the "softest hand" (hot split) and they got the sample pack out in the mail the same day.

I received the sample transfers a few days later via Priority Mail. Their package included their stock design catalog which allows you to easily customize logos, sports mascots, stock icons with your own name and/or sport team name. Perfect for selling printing services to local schools, sports teams, etc.

Once again I fired up the Phoenix Phire Heat Press to the temperature specified in the instructions provided by Transfer Express.

Here's a picture of the hot split transfer before:

This time the transfer pressed to the shirt with no problems. The transfer backing peeled of smoothly (like butter). Here's an after photograph:

Even ink coverage, very soft hand. It even smooshed into the garment nicely:

There was very little ink left on the transfer release paper after pressing with the Transfer Express hot split as compared to the others I tried:

I then tried one of their single color "Goof Proof®" transfers:

Another butter transfer Peeled easily, only required 4 seconds of press time, and it came out looking great:

Peeled easily, only required 4 seconds of press time, and it came out looking great:

The pricing at Transfer Express was a bit higher than some of the other companies, and the gang sheets weren't as large, but the ease of use of the transfers was definitely at the top of the list!

VersaTrans

Website: Custom Transfers - Welcome - Versatrans

Phone: 1-888-414-7604

Presentation of Sample Package -

![Image]()

Responsiveness -

![Image]()

Transfer Ease of Use For This Newbie -

![Image]()

Likelihood I'd Use Them on Future Orders -

![Image]()

Variety of Custom Transfer Printing Services -

![Image]()

*Quality -

![Image]()

I sent my first email to VersaTrans using their online contact form and it bounced back to me as an invalid email address. After reading about better experiences with them here, I decided to give them a call.

I talked to Mark, their production manager and after talking a bit about their services and my needs, he said he would send out a sample pack.

I never heard from them again (except for the occasional promotional email they now send me).

It's interesting to note that the only two companies that I had to (reluctantly) contact via phone to get samples were the only two companies that didn't follow through. Confirming my theory that email is better

UPDATE 3-16-2007: As I reported in this post earlier, I got a sample package and letter sent from Mark at Versatrans. The letter said that the first sample package was returned by the post office as undeliverable, so they resent it via UPS.

The package from versatrans included a very nice selection of samples and some great information for selling transfers. I actually got the "My Marketing Kit", which is a package they sell on their site to help you market your transfer printing services.

The plastisol transfer types I received were:

- Their "versatrans" brand which is a hot peel

- Their "Error Proof Transfer" EPT which is a thicker hot peel

- Glitter

- Foil (very neat)

- Flexabond (for jerseys/polyester)

- Neon

The first transfer I tried was the Error Proof Transfer.

I fired up my press according to the instructions and laid out the transfer on the shirt. A quick press for a few seconds and the transfer peeled like butter

Hardly any ink left on the transfer paper.

The design on the shirt looked great as well:

The ink coverage on the error proof transfer was thick, but not too thick. It would work for a wide variety of uses, but maybe not all "fashion" prints.

My next transfer I tried was the foil transfer because it looked so cool and shiny. The instructions were a bit daunting, but I gave it a shot :

:

Before it was pressed:

One interesting part in the pressing instructions from VersaTrans was that they recommended pre-heating not only the t-shirt, but actually pre heating the bottom platen for several seconds before you even put the shirt on the press.

This worked suprisingly good, and it made it so that the shirt didn't need as long of a pre-press to remove moisture, since it was getting heat from the bottom of the press.

After I pressed the foil, the transfer peeled off smoothly:

The design on the shirt looked nice as well:

Next you had to take the foil and put it on the design so the foil gets transferred to only the design areas and the re-press for a few seconds:

The final result was shiny, but I think it wasn't as shiny as it's supposed to be (if it was supposed to look just like the gold foil color):

I think I'd like to try more of these foil transfers later, because it seems like they'd have a nice effect when done right.

Last, but not least, I tried the VersaTrans signature hot peel transfer:

Here's a picture of the transfer before it got pressed:

The transfer peeled perfectly and looked great on the shirt:

Out of all the transfers from VersaTranz, this one had the softest hand, and felt the nicest on the shirt. Definitely worthy of a fashion print:

Even after the initial communication mixup, I was pretty impressed with the service and transfers from VersaTrans. I think they have the lowest minimum of all the transfer companies I've tried so far. Their pricing sheet starts at just 2 custom transfers. They have a design book for working with local teams and clubs, they have some nice specialty printing like glow in the dark, reflective, neon, etc and they have free gang sheets which means you can gang several images on their "jumbo" (11.5" x 17.5") transfer sheet at no extra charge.

F & M Expressions Unlimited

Website: Welcome to fmexpressions.com

Phone: 1-888-788-7133

Presentation of Sample Package -

![Image]()

Responsiveness -

![Image]()

Transfer Ease of Use For This Newbie -

![Image]()

Likelihood I'd Use Them on Future Orders -

![Image]()

Variety of Custom Transfer Printing Services -

![Image]()

*Quality -

![Image]()

After receiving a Private Message via the forum from Zach Ellsworth of F & M Expressions, I decided to get some samples from their company as well. I figured with the last name "Ellsworth" (brother to resident heat press expert, Josh Ellsworth), I couldn't go wrong

I got a package a few days later from a company called NumberAlls and I got a little worried that my information had been sold to other transfer companies. After a little research I figured out that NumberAlls is just a sister company to F & M Expressions Another employee of the company joined the forum recently which helped me to understand the relation between the two company names.

Another employee of the company joined the forum recently which helped me to understand the relation between the two company names.

The first transfer I tried was a hot peel stock design. I followed the included instructions exactly and preheated the press and the garment.

Here's the before transfer:

And here's the nifty t-shirt I made for myself:

It pressed to the garment perfectly and seemed to have a neat little "puff" to the design:

I was so excited about getting a t-shirt right that I changed into the DAD shirt and wore it the rest of the day

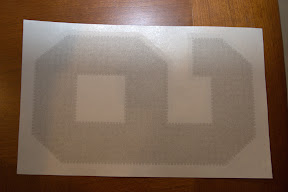

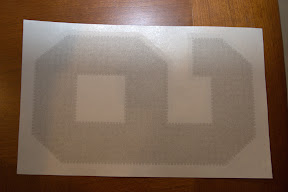

Next I tried a number 9 transfer (or maybe it was a number 6?):

I got brave after my last successful transfer so I pressed this one on a lightweight District Threads t-shirt and it turned out pretty nice:

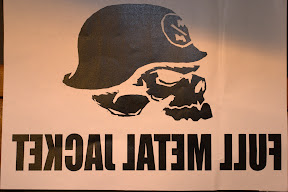

The last transfer that I did from F & M sort of intrigued me because it looked like it had 13-14 colors!

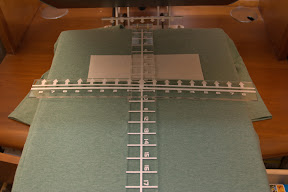

I had usually been "eyeballing" the transfers to see if they were lined up. I figured I needed the practice trying to get an eye for alignment. So this is my eyeballed alignment:

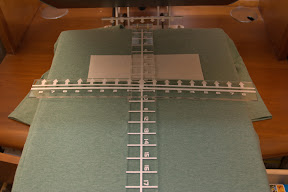

Then I decided to check my alignment with Lou's Tee Square It transfer alignment tool, and I was pretty surprised at how far off I was:

I realized that I don't have an eye for alignment

After pressing the transfer, which F & M calls its "Freedom" transfer line, I was pretty surprised at the color range:

F & M Expressions has pretty competitive transfer pricing and offers large gang sheets so you can save money by fitting several of your designs on one transfer sheet. Their "Freedom" transfers are actually NOT priced by the number of colors in the design. So if your design has anywhere from 3 colors to 99+ colors, it's priced at the "Freedom" transfer price. I'm not sure exactly how they do this, but it seems pretty neat.

I actually placed my first ever custom transfer order with F & M and the process was pretty painless All done via email except for the billing information.

All done via email except for the billing information.

Image Setters

Website: N/A

Phone: (310) 217-0363

Presentation of Sample Package -

![Image]()

Responsiveness -

![Image]()

Transfer Ease of Use For This Newbie -

![Image]()

Likelihood I'd Use Them on Future Orders -

![Image]()

Variety of Custom Transfer Printing Services -

![Image]()

*Quality -

![Image]()

Last but not least, I was able to get some samples from Image Setters. I contacted Jimmy (mr.4colorprocess) via Private Message and talked to him about what kind of transfers Image Setters does and what kind I was interested in and he agreed to send out some samples for me to try.

One cool thing about Image Setters is that they are also located in California like I am, so the shipping times are pretty fast to my location.

I got the package from Image Setters a couple of days later and it included a handful of custom printed labels and a couple of full size transfers. They also included 2 transfers actually printed on t-shirt material to show how the transfers looked when pressed.

The first transfer I tried was a one color, white ink, hot peel transfer. The transfer came a bit folded, but it seemed to press just fine:

After pressing for a few seconds. Easy to peel:

Nice smooth ink coverage:

The next one I tried was a 2 color ink, hot peel transfer:

Once again I got another easy to peel, smooth like butter transfer:

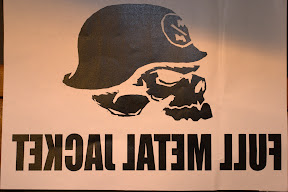

I was feeling kind of brave again, so I decided to try pressing the next one color (black ink) hot peel transfer of a seam to see how it held up.

It did surprisingly well for being pressed on over a seam. I think that might be one benefit to pressing a screen printed transfer as opposed to squeeging a screen print directly to the shirt, over a seam. The downward force is a bit easier to apply rather than a pushing ink horizontally over the bumpy area:

With a bit more pressue, I think it would have came out perfectly:

Image Setters does a lot of custom plastisol transfers for big name companies like Tony Hawk and Disney, including a lot of custom neck tag labels for apparel companies. They have a $250 minimum order, but you can get a whole bunch of transfers for that price

Thanks to all the companies that took the time to send out transfers. It really helps to decide which ones will work for your particular transfer needs.

I hope this little review is helpful for some. Any questions at all, feel free to post them below!

It's one thing for me to read all the threads here and have "book knowledge" of how heat transfers work; I'm finding it something totally different to actually press transfers to shirts.

First Lesson

The first thing I learned about plastisol transfers was that not all plastisol transfers are equal. Not that I got poor quality transfers, just that not all transfers are as easy to apply (for a newbie like me) as others.

I think for some reason I expected I would heat up my press, pre-heat the garment, press the transfer for a few seconds, and viola, there's my perfect shirt.

My reality was that there is a lot more testing of temperature, getting the right pressure, testing how long to press (dwell times), figuring out how fast to peel it off on a hot peel or how cool to let the transfer get for a cold peel.

On To The Plastisol Transfer Tests

Companies contacted:

First Edition

Dowling Graphics

Howard Sportswear

KE Moto Graphics

Transfer Express

VersaTranz

FMExpressions

Image Setters

Criteria:

For this review, I'm going to make up some very unscientific newbie criteria to rate each company on

Presentation of Sample Package - includes number of transfers, instructions, variety, company information, ordering information received, pricing info received. Basically my impression of how complete the information was that I received that would help me do business with the company.

Responsiveness - how fast the company responded to all email and/or phone communication. This also includes how fast the samples arrived.

Transfer Ease of Use For This Newbie - this was one of the most important factors for me. Simply put, how easy it was for me (a complete newbie to heat pressing transfers) to press a transfer that I would feel comfortable selling to a retail customer. If I could follow the instructions they sent and get the desired result with very little "messing around" (pressure, changing temperature, testing dwell times, etc), they got a higher rating here.

Likelihood I'd Use Them on Future Orders - how likely I would use the company for future custom transfer orders.

Variety of Custom Transfer Printing Services - how varied their screen printed transfer printing services were based on the information I received. Like do they do rhinestones, stock transfers, hot peel, puff, 4+ color transfers, existing designs you can customize to fit your needs, etc.

*Quality - overall quality of the transfers

A Note On Quality:

You'll probably notice the big red asterisk next to "quality" That's because since I'm so new at pressing transfers, it's really hard to say what is a bad quality transfer and what is user error (the most likely cause for my particular issues), but at the same time it would seem weird to leave quality out of the criteria. I think once I get more experience with using the heat press, I'll be able to better judge the overallquality. All of the transfers held up great after one wash and didn't have any cracking. It just seemed that some were easier to apply than others.

That's because since I'm so new at pressing transfers, it's really hard to say what is a bad quality transfer and what is user error (the most likely cause for my particular issues), but at the same time it would seem weird to leave quality out of the criteria. I think once I get more experience with using the heat press, I'll be able to better judge the overallquality. All of the transfers held up great after one wash and didn't have any cracking. It just seemed that some were easier to apply than others.

You'll probably notice the big red asterisk next to "quality"

Reviews:

First Edition Screenprinting

Website: First-Edition.com

Phone: 1-800-872-6760

Presentation of Sample Package -

Responsiveness -

Transfer Ease of Use For This Newbie -

Likelihood I'd Use Them on Future Orders -

Variety of Custom Transfer Printing Services -

*Quality -

After my initial hurdles contacting First-Edition Screen Printing by email (later solved by Badalou

Out of all the sample packages I received, the package from First Edition was the most informative. They sent a binder that had information on the company history, detailed information on the different transfer types, a huge variety of sample transfers for me to try and even a sample printed t-shirt.

They sent cold peel, hot split, double print hot split, glitter, transfers for nylon, sample numbers, all kinds of good stuff.

The first transfer I tried from First Edition was one of the hot split transfers.

I pre-heated the press, pre heated the garment to get the moisture out, followed the instructions and didn't do too well on my first try:

I have to admit I was slightly disappointed at this point, since I had it in my mind that they would "just work". After talking (via email) with Janet from First Edition and reading through the info they provided, it can sometimes take a bit of testing of temperatures, pressure settings and dwell times to get transfers to come out right.

I found it's sort of like those instructions that come with Microwave meals that tell you that their instructions were for a 1000 watt microwave, so you may need to adjust your results based on your microwave brand and wattage. Not all heat presses heat the same or give the same pressure, so there will be times when you need to fiddle around with it to see what works.

I decided to come back to the First Edition transfers a a few days later once I had a better hang of things. I also had to do a better job of taking before and after photos

This time I tried one of the hot split transfers and got a bit better result:

I still wasn't getting enough ink on the shirt and consistency was still off.

The actual feel of the print on the shirt was very nice though:

I adjusted the pressure a bit and increased the temperature and tried another of the same type transfer:

The results were a bit better, but still not perfect:

A few more adjustments to the pressure and an increased dwell time (how long to press the transfer) and I got a much better result:

Overall, I thought First Edition was very helpful in answering my questions, sent out a great sample package, but I feel like the transfers are a bit too tricky for my current heat press experience level.

Dowling Graphics, Inc

Website: DowlingGraphics.com

Phone: 1-800-749-6933

Presentation of Sample Package -

Responsiveness -

Transfer Ease of Use For This Newbie -

Likelihood I'd Use Them on Future Orders -

Variety of Custom Transfer Printing Services -

*Quality -

Dowling Graphics was the first company to get back to me via my email inquiry. I got my plastisol transfer samples a few days after the confirmation email I received from them.

Their sample transfer package included some very nice full sized transfer sheets with a variety of full color stock images. They included their pricing sheet, stock catalogs even some very cool rhinestud transfers. I would have to say that Dowling Graphics included the most complex transfer designs (multi-colored) which helped to show their full color capabilities.

The first transfer I tried from Dowling Graphics was one of their hot split transfers. This picture is of the transfer sheet AFTER it was applied:

The transfer almost came out right on the first try. I don't think enough of the ink transferred to the shirt and when I hot peeled the transfer, it seemed to pull the ink off the shirt a bit:

A closer look shows some of the areas of the design that were missing ink or that were a bit patchy.

Most of the design transferred well though. I really think with more practice, they would come out perfect:

My next try with the same type transfer didn't come out as well. Here's the "before":

Here's a closeup of the transfer sheet:

Here are some "after" photos. Again, not enough of the ink transferred to the shirt which left splotchy areas in the finished design:

I had similar hit and miss results with their hot peel transfers for white/light garments.

Here's a before picture of the transfer sheet:

And an after picture that shows the light ink coverage:

I did get one transfer for light t-shirts to come out just about perfect.

The pressed transfer:

Unfortunately, I don't remember the exact settings I needed to get it to come out "just right".

I was very impressed with the rhinestone/rhinestud type transfers that Dowling Graphics sent. Initially I didn't see the appeal of this type of decoration, but after seeing how easy it was to apply, and how it looked on a finished t-shirt, I could see offering custom rhinestud transfers (or even stock ones) for sale. With the right creativity, I could see how you could combine a rhinestone/crystal transfer with a plastisol transfer to create a really nice finished design.

Here's the transfer sheet:

And a few pictures of the finished rhinestone transfer on a maroon teeshirt. Since this tshirt didn't have a side seam, I actually pressed this transfer as a "wrap around" design that is partly on the front and partly on the back of the tee.

I even made a cute t-shirt for my daughter

Once I get better at the hot split transfers, I could see myself ordering from Dowling Graphics. Out of the hot peel, hot split and cold peel transfers I tried, I liked the feel of the hot split transfer the best.

I really liked the rhinestone transfers. I don't know if they do custom rhinestone transfers, but it's something I would look into for certain designs now that I've seen it in action.

Howard Sportswear Graphics Express, Inc

Website: Howard Sportswear Graphics

Phone: 1-866-695-8196

Presentation of Sample Package -

Responsiveness -

Transfer Ease of Use For This Newbie -

Likelihood I'd Use Them on Future Orders -

Variety of Custom Transfer Printing Services -

*Quality -

I initially emailed Howard Sportswear and got an email back from them a few days later asking me to call them for more info. I'm normally an email kinda guy, but I had heard good things about their company from posts here in the forums, so I gave them a call.

I talked to one of their employees who gave me some good information about the company, asked me about my needs, and said she would send out a sample pack. I never heard from them again.

UPDATE (3=16-07): After I heard back from Versatranz, I decided to email Howard Sportswear this week to see what happened to my samples.

I got an email back pretty quick that said that they held up sending the samples because they were waiting on new catalogs to be printed, but if I wanted, they could send me the samples without the catalog. I wish they would have followed up earlier to let me know about the delay, but at least now I know what happened. I got a shipment notification today that the sample pack was shipped.

KE Motographics

Website: K E Motographics prints custom heat transfers using your artwork, as well as printing directly onto clothing. We can print either screenprinted heat transfers or color laser heat transfers. Give us a call or send an email to discuss which is best for

Phone: 1-800-563-1873

Presentation of Sample Package -

Responsiveness -

Transfer Ease of Use For This Newbie -

Likelihood I'd Use Them on Future Orders -

Variety of Custom Transfer Printing Services -

*Quality -

Thanks to Jasonda, I was able to get in contact with this custom transfer supplier from the west coast. They got back to my initial email pretty quickly and followed up questions to make sure I got the right samples that would demonstrate their work. Nice friendly, down to earth emails.

The samples I got from the company came in a plain letter sized envelope with a packing slip and a few 1-2 color hot peel transfers.

I fired up my heatpress and followed their instructions to test their transfers.

Here's the before transfer:

And a near perfect after transfer photo:

I say "near" perfect because I think I may not have had enough pressure. It seems like this transfer sat on top of the shirt more than I thought it should.

I think with a bit more pressure, and maybe even setting the temperature a bit hotter, the ink would have smooshed (technical term

Although, the KE Motographics "package" was very simple and to the point, their transfers worked pretty well on the first go without much fiddling.

Stahl's Transfer Express

Website: transferexpress.com

Phone: 1-800-622-2280

Presentation of Sample Package -

Responsiveness -

Transfer Ease of Use For This Newbie -

Likelihood I'd Use Them on Future Orders -

Variety of Custom Transfer Printing Services -

*Quality -

The folks from TransferExpress got back to me the same day I sent out an email requesting more information. They answered my question on which of their transfers offered the "softest hand" (hot split) and they got the sample pack out in the mail the same day.

I received the sample transfers a few days later via Priority Mail. Their package included their stock design catalog which allows you to easily customize logos, sports mascots, stock icons with your own name and/or sport team name. Perfect for selling printing services to local schools, sports teams, etc.

Once again I fired up the Phoenix Phire Heat Press to the temperature specified in the instructions provided by Transfer Express.

Here's a picture of the hot split transfer before:

This time the transfer pressed to the shirt with no problems. The transfer backing peeled of smoothly (like butter). Here's an after photograph:

Even ink coverage, very soft hand. It even smooshed into the garment nicely:

There was very little ink left on the transfer release paper after pressing with the Transfer Express hot split as compared to the others I tried:

I then tried one of their single color "Goof Proof®" transfers:

Another butter transfer

The pricing at Transfer Express was a bit higher than some of the other companies, and the gang sheets weren't as large, but the ease of use of the transfers was definitely at the top of the list!

VersaTrans

Website: Custom Transfers - Welcome - Versatrans

Phone: 1-888-414-7604

Presentation of Sample Package -

Responsiveness -

Transfer Ease of Use For This Newbie -

Likelihood I'd Use Them on Future Orders -

Variety of Custom Transfer Printing Services -

*Quality -

I sent my first email to VersaTrans using their online contact form and it bounced back to me as an invalid email address. After reading about better experiences with them here, I decided to give them a call.

I talked to Mark, their production manager and after talking a bit about their services and my needs, he said he would send out a sample pack.

I never heard from them again (except for the occasional promotional email they now send me).

It's interesting to note that the only two companies that I had to (reluctantly) contact via phone to get samples were the only two companies that didn't follow through. Confirming my theory that email is better

UPDATE 3-16-2007: As I reported in this post earlier, I got a sample package and letter sent from Mark at Versatrans. The letter said that the first sample package was returned by the post office as undeliverable, so they resent it via UPS.

The package from versatrans included a very nice selection of samples and some great information for selling transfers. I actually got the "My Marketing Kit", which is a package they sell on their site to help you market your transfer printing services.

The plastisol transfer types I received were:

- Their "versatrans" brand which is a hot peel

- Their "Error Proof Transfer" EPT which is a thicker hot peel

- Glitter

- Foil (very neat)

- Flexabond (for jerseys/polyester)

- Neon

The first transfer I tried was the Error Proof Transfer.

I fired up my press according to the instructions and laid out the transfer on the shirt. A quick press for a few seconds and the transfer peeled like butter

Hardly any ink left on the transfer paper.

The design on the shirt looked great as well:

The ink coverage on the error proof transfer was thick, but not too thick. It would work for a wide variety of uses, but maybe not all "fashion" prints.

My next transfer I tried was the foil transfer because it looked so cool and shiny. The instructions were a bit daunting, but I gave it a shot

Before it was pressed:

One interesting part in the pressing instructions from VersaTrans was that they recommended pre-heating not only the t-shirt, but actually pre heating the bottom platen for several seconds before you even put the shirt on the press.

This worked suprisingly good, and it made it so that the shirt didn't need as long of a pre-press to remove moisture, since it was getting heat from the bottom of the press.

After I pressed the foil, the transfer peeled off smoothly:

The design on the shirt looked nice as well:

Next you had to take the foil and put it on the design so the foil gets transferred to only the design areas and the re-press for a few seconds:

The final result was shiny, but I think it wasn't as shiny as it's supposed to be (if it was supposed to look just like the gold foil color):

I think I'd like to try more of these foil transfers later, because it seems like they'd have a nice effect when done right.

Last, but not least, I tried the VersaTrans signature hot peel transfer:

Here's a picture of the transfer before it got pressed:

The transfer peeled perfectly and looked great on the shirt:

Out of all the transfers from VersaTranz, this one had the softest hand, and felt the nicest on the shirt. Definitely worthy of a fashion print:

Even after the initial communication mixup, I was pretty impressed with the service and transfers from VersaTrans. I think they have the lowest minimum of all the transfer companies I've tried so far. Their pricing sheet starts at just 2 custom transfers. They have a design book for working with local teams and clubs, they have some nice specialty printing like glow in the dark, reflective, neon, etc and they have free gang sheets which means you can gang several images on their "jumbo" (11.5" x 17.5") transfer sheet at no extra charge.

F & M Expressions Unlimited

Website: Welcome to fmexpressions.com

Phone: 1-888-788-7133

Presentation of Sample Package -

Responsiveness -

Transfer Ease of Use For This Newbie -

Likelihood I'd Use Them on Future Orders -

Variety of Custom Transfer Printing Services -

*Quality -

After receiving a Private Message via the forum from Zach Ellsworth of F & M Expressions, I decided to get some samples from their company as well. I figured with the last name "Ellsworth" (brother to resident heat press expert, Josh Ellsworth), I couldn't go wrong

I got a package a few days later from a company called NumberAlls and I got a little worried that my information had been sold to other transfer companies. After a little research I figured out that NumberAlls is just a sister company to F & M Expressions

The first transfer I tried was a hot peel stock design. I followed the included instructions exactly and preheated the press and the garment.

Here's the before transfer:

And here's the nifty t-shirt I made for myself:

It pressed to the garment perfectly and seemed to have a neat little "puff" to the design:

I was so excited about getting a t-shirt right that I changed into the DAD shirt and wore it the rest of the day

Next I tried a number 9 transfer (or maybe it was a number 6?):

I got brave after my last successful transfer so I pressed this one on a lightweight District Threads t-shirt and it turned out pretty nice:

The last transfer that I did from F & M sort of intrigued me because it looked like it had 13-14 colors!

I had usually been "eyeballing" the transfers to see if they were lined up. I figured I needed the practice trying to get an eye for alignment. So this is my eyeballed alignment:

Then I decided to check my alignment with Lou's Tee Square It transfer alignment tool, and I was pretty surprised at how far off I was:

I realized that I don't have an eye for alignment

After pressing the transfer, which F & M calls its "Freedom" transfer line, I was pretty surprised at the color range:

F & M Expressions has pretty competitive transfer pricing and offers large gang sheets so you can save money by fitting several of your designs on one transfer sheet. Their "Freedom" transfers are actually NOT priced by the number of colors in the design. So if your design has anywhere from 3 colors to 99+ colors, it's priced at the "Freedom" transfer price. I'm not sure exactly how they do this, but it seems pretty neat.

I actually placed my first ever custom transfer order with F & M and the process was pretty painless

Image Setters

Website: N/A

Phone: (310) 217-0363

Presentation of Sample Package -

Responsiveness -

Transfer Ease of Use For This Newbie -

Likelihood I'd Use Them on Future Orders -

Variety of Custom Transfer Printing Services -

*Quality -

Last but not least, I was able to get some samples from Image Setters. I contacted Jimmy (mr.4colorprocess) via Private Message and talked to him about what kind of transfers Image Setters does and what kind I was interested in and he agreed to send out some samples for me to try.

One cool thing about Image Setters is that they are also located in California like I am, so the shipping times are pretty fast to my location.

I got the package from Image Setters a couple of days later and it included a handful of custom printed labels and a couple of full size transfers. They also included 2 transfers actually printed on t-shirt material to show how the transfers looked when pressed.

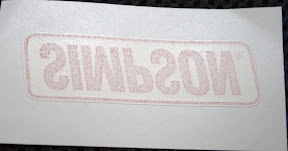

The first transfer I tried was a one color, white ink, hot peel transfer. The transfer came a bit folded, but it seemed to press just fine:

After pressing for a few seconds. Easy to peel:

Nice smooth ink coverage:

The next one I tried was a 2 color ink, hot peel transfer:

Once again I got another easy to peel, smooth like butter transfer:

I was feeling kind of brave again, so I decided to try pressing the next one color (black ink) hot peel transfer of a seam to see how it held up.

It did surprisingly well for being pressed on over a seam. I think that might be one benefit to pressing a screen printed transfer as opposed to squeeging a screen print directly to the shirt, over a seam. The downward force is a bit easier to apply rather than a pushing ink horizontally over the bumpy area:

With a bit more pressue, I think it would have came out perfectly:

Image Setters does a lot of custom plastisol transfers for big name companies like Tony Hawk and Disney, including a lot of custom neck tag labels for apparel companies. They have a $250 minimum order, but you can get a whole bunch of transfers for that price

Thanks to all the companies that took the time to send out transfers. It really helps to decide which ones will work for your particular transfer needs.

I hope this little review is helpful for some. Any questions at all, feel free to post them below!